|

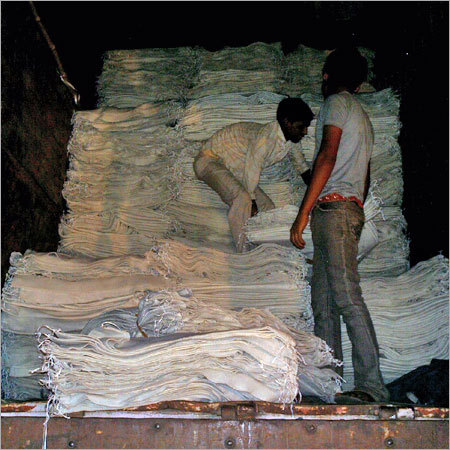

Geotextile Filter Fabric

Product Details:

Product Description

Geotextile Filter Fabric

We are engaged in manufacturing and supplying an extensive range of Geo textile Fabrics that are developed using high grade polypropylene staple fibers. These fibers are bonded mechanically by using needle punching, which helps in developing a highly strong, dimensionally precise and flexible fabric structure.

Due to its optimal pore size, these geo textile fabrics are resistant to all kinds of biological organisms that are found in abundance in soil. Besides, our range is appreciated by various domestic as well as private institutions for its degradation stabilization that occurs because of the short-term ultra-violent radiation exposure.

| Test Parameter | Unit | Spec. | Results | As per Std. |

| Mass (GSM) | g/m2 | 300 | 305 | ASTM D 5261 |

| Thickness | mm | 2 | 2.2 | Nil |

| Tensile strength MD | KN/M | 9 | 10.2 | ASTM D 4595 |

| Tensile strength CD | KN/M | 9 | 11.7 | Nil |

| Elongation MD | % | 50.00% | 85 | Nil |

| Elongation CD | % | 50.00% | 80 | Nil |

| Static puncture | N | 1400 | 1402 | ASTM D 6241 |

| Permittivity |

| 1.25 | 1.27 | ASTM D 4491 |

| UV Resistance | % | 500hrs | 73 | ASTM D 4355 |

| Apparent Opening Size | um |

| 105 | ASTM D 4751 |

| Bag Dimension | Mtr |

| 1mtrx0.72mtr | Nil |

The aforementioned values are applicable with effect from 1-01-2012. These values are basically the average roll values wherein all the properties possess + - 10% water permeability and tolerance. Moreover, the elongations have -30% tolerance and the AOS holds + 30%.

Features

- Chemical resistance.

- Effective usage for preventing soil erosion.

Other Products in 'Geotextile Fabrics' category

GST : 07ACVPG3641G1ZH

|

|

|

|

AANCHAL INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |